You are here: English > Cold Chain > Airfreight cold chain payload

When time-temperature sensitive products are shipped with air freight cargo, not only the temperature protection of the products is important but also the payload. Air freight is a fast and efficient way of transport yet it has also a price-tag. This price is depending on the payload which is determined by the volume of the shipment and the weight. If a passive packaging system is used as temperature protection the question needs to asked what the packaging will do to the payload.

When we talk about passive cooling we mean that no electrical or mechanical systems as cooling engines are used to cool the surrounding air on the temperature sensitive products and that the temperature of the products is protected from unwanted external temperatures with insulation materials designed as a packaging. On the page "Air cargo pharma", the different passive packaging systems are explaned being a "HCCP-packaging" system with "Thermal Re-load Locations" which offers a thermal protection during the HCCP's "Hazardous Critical Control Points" in the cold chain, and a total cold chain protection passive cooling system.

Thermal blankets and thermal covers as ideal temperature & payload relation

More and more companies who produce or transport time-temperature sensitive products and use airfreight are considering the usage of thermal blankets or thermal covers because of the ideal temperature protection and payload relation. Below you can find some of the mayor advantages when thermal blankets are used as a passive packaging system on for example Euro or US-Block pallets.

Thermal blankets use the thermal energy of the shipment

When using thermal blankets or thermal covers as passive cooling system, the main goal of the thermal blankets is to use the available thermal energy of the goods and protect this as long as possible against the thermal influences of the external temperature. If you look at other passive cooling packaging systems it is mostly the thermal energy of added packs such as gel packs, ice packs, cool packs, which is used for offering the required temperature preservation. This build-up will of course offer a long and effective temperature protection, yet the adding of these packs will add weight and volume to the shipment meaning that these packs have a significant impact on the payload and further the transport cost of the shipment. This impact on the payload is avoided when thermal blankets or thermal covers are used as a passive packaging system when “Thermal Re-loads” are possible in the cold chain and explains why thermal blankets and thermal covers are more and more employed in the air cargo or airfreight of time-temperature sensitive products such as pharmaceuticals or healthcare products (chilled and ambient), perishable food products, chemicals, etc… Temax engineering offers the possibility to pre-study the total cold chain to see if thermal reloads are possible so thermal blankets can be used.

Thermal blankets adapt to the shipment dimensions

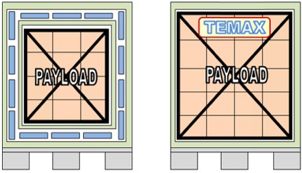

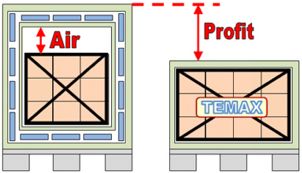

Another advantage of thermal blankets and thermal covers is that they adapt to the dimensions of the shipment. The blankets are wrapped around the pallet so the shipment has an ideal payload and a minimal space is lost. If other passive cooling systems are used such as pre-build boxes for example, the shipment needs to be adjusted to these boxes. If not, lots of air volume will be in the box which influences the volume and again the payload and cost of the transport. Temax engineering offers the possibility to calculate the ideal insulation quality or better the ideal insulation thickness (insulation configuration) of the Temax material that needs to be used in order to maintain the required temperatures in the cold chain. This makes it possible to create the most ideal temperature protection and payload relation or the most cost effective transport system.

What are thermal blankets?

Thermal blankets are blankets with a certain insulation quality which are used to insulate or protect temperature sensitive goods as pharmaceuticals and perishables which need to be transported in a certain temperature controlled environment. Thermal blankets are common used in the air cargo or air freight as a passive cooling or passive packaging system to protect the temperature of temperature sensitive goods against unwanted external temperatures and weather conditions. The used insulation quality of the thermal blanket is determined by the required temperatures and the transport conditions. The thermal blankets can be used as a wrapping foil or can be made tailor made as covers for all kind of cargo carriers as Euro or US block pallets, airplane pallets, cargo containers, etc… as used in the air freight or air cargo.

Thermal blankets can be used in a cold chain with active or passive cooling. When active cooling is used in the cold chain, HCCP’s (Hazardous Critical Control Points) will appear in the chain in which the temperature of the goods fluctuates. To decrease these fluctuations or HCCP’s, thermal blankets are used to provide an extra protection. When passive cooling is used, thermal blankets are used as a passive packaging and provide a temperature protection during the total cold chain. More and more companies are implementing thermal blankets as passive cooling systems for closing the cold chain and maintaining the required product and temperature quality.

Validated thermal blankets for TARMAC temperature protection in air cargo – airfreight

The TEMAX special designed multilayer (4x radiant barriers) thermal blankets and thermal covers are also validated by several of our customers. Several major pharmaceutical companies have validated the Temax thermal blankets for temperature protection on the tarmac on airfields. The validations were performed on ambient temperature pharmaceuticals, healthcare products and life science products where the goal was to maintain the required product temperature within its maximal (summer profile) and minimal (winter profile) temperature range. The Temax thermal blankets are also validated by a global fruit supplier for soft fruit shipments such as strawberries, blue berries, cherries, etc... A chemical company has validated the Temax thermal blankets for a non-freezing application where several tests were performed to create repetition test results.