You are here: English > Cold Chain > Airfreight cold chain

If you send a package with temperature sensitive goods like conditioned food products, chemicals or pharmaceuticals by air freight cargo from, let’s say Brussels to for example Singapore, you could be surprised of the different external temperatures that are surrounding your goods during its transport and storrages at the different airports. In the cargo of an airplane for example, the temperature can fluctuate if the cargo is not conditioned. At the airport, when the package is placed on the airfield for loading and unloading or overloading (Tarmac times), the goods are standing in the open air in which temperatures of +50°C can appear in warm countries or even a -30°C in cold countries. If you then realize that the loading or unloading process on airplanes can take several hours, where the products are standing in the open air creating a serious HCCP "Hazardous Critical Control Point" in the cold chain, you will notice that during this loading or unloading process the temperature of your products can increase or decrease significant. The question that needs to be asked is how this temperature excursion will affect the quality of your products.

Pharmaceuticals and healthcare in airfreight

When time-temperature sensitive pharmaceuticals or healthcare products, such as chilled (+2°C to +8°C) or ambient (+15°C tot +25°C), are transported with air freight the choice can be made to transport with an active cooling (cooler engines) or passive cooling (insulated packaging) system or a combination of both. The choice of the kind of cooling system is not only depending on the temperature requirements but also on the equipment which is available at the actors in the temperature controlled supply chain, also known as cold chain. If the actors, such as freight forwarders, transport companies, warehouses, distribution centers, air freighters etc…, can provide temperature controlled storage or transport in which they can also cover the important HCCP's "Hazardous Critical Control Points" at overload procedures for example, the choice for active cooling could be made. If not, a passive cooling system would be advisable. In these passive cooling systems two mayor solutions can be used.

Single temperature excursion passive cooling system (HCCP-packaging)

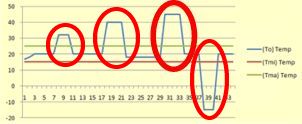

A first possible passive cooling system which can be used is a system which offers a temperature protection during the HCCP’s in the cold chain. These are Hazardous Critical Control Points where the external or outer temperature, surrounding the products, is lower or higher than the temperature barriers of the products (+2°C to +8°C) or (+15°C to +25°C). It is at these points that the temperature of the product can rise or sink below the temperature barriers leading to quality damages, which needs to be avoided. These HCCP’s mostly appear in the cold chain when active cooling is used, yet where the products are standing unprotected in extreme external environments. Overload procedures in the cold chain where the products are loaded or unloaded from one temperature controlled environment into another create such HCCP’s. A good example of such overload procedure is the TARMAC TIME on airfields where pallets with time-temperature sensitive goods are standing unprotected on the tarmac of an airfield waiting to be loaded into an airplane. These tarmac times can be several hours and in extreme hot or extreme cold temperatures. This will certainly have an impact on the temperature of the time-temperature sensitive pharmaceuticals or healthcare products. To prevent an extreme temperature rise or drop, a thermal insulation protection is required. These kinds of protections we call "HCCP-packaging" systems and offer protection for a single peak or single temperature excursion as shown in the graphic above (red circles = temperature protection with HCCP-packaging).

A first possible passive cooling system which can be used is a system which offers a temperature protection during the HCCP’s in the cold chain. These are Hazardous Critical Control Points where the external or outer temperature, surrounding the products, is lower or higher than the temperature barriers of the products (+2°C to +8°C) or (+15°C to +25°C). It is at these points that the temperature of the product can rise or sink below the temperature barriers leading to quality damages, which needs to be avoided. These HCCP’s mostly appear in the cold chain when active cooling is used, yet where the products are standing unprotected in extreme external environments. Overload procedures in the cold chain where the products are loaded or unloaded from one temperature controlled environment into another create such HCCP’s. A good example of such overload procedure is the TARMAC TIME on airfields where pallets with time-temperature sensitive goods are standing unprotected on the tarmac of an airfield waiting to be loaded into an airplane. These tarmac times can be several hours and in extreme hot or extreme cold temperatures. This will certainly have an impact on the temperature of the time-temperature sensitive pharmaceuticals or healthcare products. To prevent an extreme temperature rise or drop, a thermal insulation protection is required. These kinds of protections we call "HCCP-packaging" systems and offer protection for a single peak or single temperature excursion as shown in the graphic above (red circles = temperature protection with HCCP-packaging).

Thermal "RE-LOADS" in a HCCP packaging system

When a HCCP-packaging system, such as for example thermal blankets of thermal covers, are used to transport time-sensitive pharmaceuticals and healthcare products (+2°C to +8°C) or ambients (+15°C to +25°C), it is important to know that only the available thermal energy of the goods / products is being used which will be protected by the HCCP-passive cooling system. This means that no additional thermal energy such as gel packs, ice packs, cold packs or cool packs for example is used and the insulation quality of the passive cooling system needs to be sufficient to offer the required temperature protection. This also means that “thermal reloads” are needed in the cold chain in order to create the optimal temperature protection and payload relation.

These “thermal reloads” are locations in the cold chain where the lost thermal energy in the single peak or single temperature excursion can be regained. This so the available thermal energy of the shipment is ready again for the next temperature excursion. To determine the impact of the temperature excursions and the required thermal force of the thermal re-load locations, we (Krautz-Temax) offer special thermal energy calculations which predict the flow of thermal energy in the total cold chain on the temperature excursions and the thermal re-load locations.

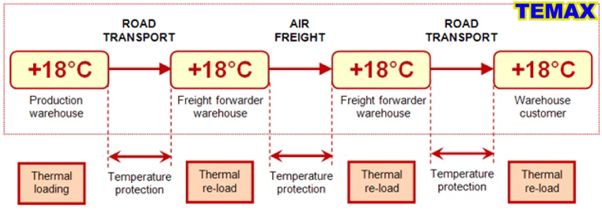

Thermal "Reloads". The big advantage with ambient pharmaceuticals (+15°C to +25°C) or (+0°C to +25°C)

Below, a cold chain is shown with ambient pharmaceuticals or healthcare products (+15°C to +25°C) or (+0°C to +25°C) temperature barriers. It also shows the temperature at the working stations at the actors in the cold chain, freight forwarders, distribution centers, warehouses, etc… where we can see that at the average working environment, where people work and operate, the temperature is about (+18°C). This is an ideal “Thermal Re-load” situation for ambient pharmaceuticals and healthcare products seeing the temperature (+18°C) is located within the temperature barriers of the pharmaceutical products (+15°C to +25°C). This also explains the reason why more and more pharmaceutical and healthcare producing companies are implementing HCCP-packaging systems and solutions. These HCCP-packaging systems such as thermal blankets and thermal covers offer these companies the ideal temperature protection and the optimal payload relation. This payload relation is also an important issue airfreight of pharmaceuticals seeing it determines the transport cost.

Total cold chain passive cooling system

Next to a HCCP-packaging system, which is mainly used to offer a temperature protection against the HCCP’s in the cold chain, a passive cooling system can also be used to offer a temperature protection during the total cold chain. These kind of passive cooling systems are mostly used in small packaging systems of chilled pharmaceuticals and healthcare products (+2°C to +8°C) seeing small volumes have not much available thermal energy and the actors in the cold chain are not always equipped to offer a temperature controlled environment of (+2°C to +8°C) meaning that the available thermal energy cannot be thermal re-loaded. Yet, this total cold chain packaging system, where extra thermal energy is added with for example gelpacks, will have a significant impact on the payload relation.

Next to a HCCP-packaging system, which is mainly used to offer a temperature protection against the HCCP’s in the cold chain, a passive cooling system can also be used to offer a temperature protection during the total cold chain. These kind of passive cooling systems are mostly used in small packaging systems of chilled pharmaceuticals and healthcare products (+2°C to +8°C) seeing small volumes have not much available thermal energy and the actors in the cold chain are not always equipped to offer a temperature controlled environment of (+2°C to +8°C) meaning that the available thermal energy cannot be thermal re-loaded. Yet, this total cold chain packaging system, where extra thermal energy is added with for example gelpacks, will have a significant impact on the payload relation.