Create two different temperatures on one roll container with BI-Temp cover

Thermal covers roll containers

- BI-FOLD - thermal cover

- Middle Closure - thermal cover

- Door closure - thermal cover

- Q-Fold - thermal cover

- No-Condens - thermal cover

- Cross-dock packaging

- Storage systems for covers

Thermal containers

- Mobi-Box thermal container

- Bi-temp thermal container

Bi-Temp Mobi-Box for flexibility in temperature controlled logistics

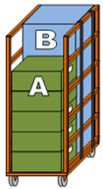

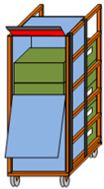

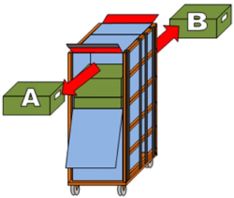

The insulated Bi-Temp Mobi-Box or Bi-temp thermo container is a half size Mobi-Box or thermal container which offers the big advantage to load products with different temperatures in just one roller container. This can be advisable for smaller deliveries. If one customer has for example a small order of frozen foods -18°c and a small order of refrigerated milk products +5°c, it all can be put on just one roller container which prevents the driver of going two times to the truck and the customer to get the different products. This creates a big saving in time and costs. The cover can be made to size according to a vertical or horizontal allignment as shown below.

Cooling & refrigeration with gel-packs or dry-ice

The semi Mobi-Box or thermal roll container can be equipped with a cooling shelve in the roof of the cover in which gel-packs or dry-ice can be placed. This creates extra cooling or refrigeration which extends the transport time of temperature preservation time significant.

MOVIE / BI-TEMP Mobi-Box / two temperatures rollcontainer

The big logistic advantage of the Mobi-Box thermo container

Seeing the Mobi-Box is tailor made according to the sizes of the roller container the customer maintains its own dimensions which is not the case when heavy solid thermo containers are used. These solid thermal containers are bigger than the dimensions of the standard roller containers and require therefore special attention in de planning of the distribution. The solid thermal containers take a lot of place in the trucks or trailers, or they take a lot of load-space. This is not the case with the Mobi-Box. It preserves the standard dimensions of the roller container which is being used. Another big advantage is the leight weight. The very light weight of the cover + roller container makes the combination aesy to handle.

You keep the dimensions of your standard roller container

The Mobi-Box thermal cover is tailor made to the dimensions of your standard roller container. This means that in your logistics, you keep the standard dimensions of the roller container. This in regards to thermo containers which have special dimensions and have an impact on the load in the trucks / trailers.

Maximal load capacity

The Mobi-box has a thickness of ca 2cm. This has the advantage that the mobi-box has a minimal impact on the load capacity of crates and boxes

Very light weight

The Mobi-box has a weight of only 15kg which makes the mobi-box a pleasure to work with. For your logistic co-workers and your customers

Removable and insulated industrial zippers

The "Mobi-Box" thermal cover is equipped with a unique removable zipper system. The industrial zippers are used to open and close the loading door of the Mobi-Box which mekes the door easy to open and to close. These zipper closures are also insulated. Yet a zipper can always be damaged meaning that the cover cannot be used again. To avoid this, the Mobi-Box has velcro removable zippers so when they are broken, they can easily be replaced

Temperature characteristics

Preservation and stabilization of the product temperature

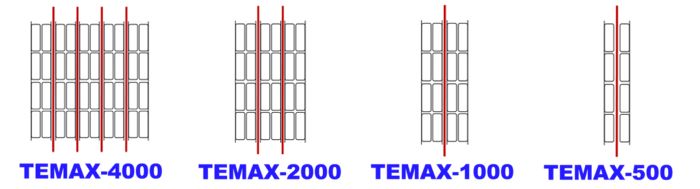

The Mobi-Box thermal covers are used to preserve or stabilize the temperature of the products, which are protected by the thermal cover, as long as possible. The time that the temperature can be preserved of stabilized, or the speed of temperature increase or decrease, is depending on the insulation quality. Thermal covers or insulated covers with middle closures are manufactured with a certain Temax insulation material which have a certain insulation quality (R-value or U(k)-value). The higher or thicker the insulation quality, the longer the time of temperature preservation or the slower the speed of temperature change of the products inside the thermal cover.

External convection flows due to open thermal bridges – cold bridges

Next to the insulation quality of the thermal cover with middle closure, the stability or deviation speed of the temperature of the product is also depending on the presents of open thermal bridges or open cold bridges on the thermal cover and packaging set-up. Open thermal bridges are locations in the design or set-up of the thermal cover where an external convection flow (air flow) can exist which has a very big impact on the speed of temperature change. It is therefore very important that open thermal bridges are avoided at all times.

Adding extra thermal energy generators - Gel Packs – Dry Ice – PCM’s Phase Change Materials

When conditioned or time-temperature sensitive products are protected from external temperature influences with a passive cooling systems such as thermal covers with middle closure systems, the goal is to purely use the available thermal energy of the products to maintain and stabilize the temperature of the products as long as possible. As we know, the result of this stabilization is depending on the insulation quality of the thermal cover combined with possible convection flows and the thermal energy of the products combined with the temperature difference (inside-outside). If the temperature cannot be maintained according to the preferred time-frame, the time can be extended by increasing the available thermal energy. This extra energy can be generated by all kind of passive cooling systems such as gel packs – ice packs – dry ice – PCM’s Phase Change Materials.

Air in the roll container = negative effect on the available thermal energy

When roll containers are filled with conditioned products, it can happen that the roll container is not completely filled. Yet the roll containers have sidebars which stand higher than the filled goods. This means that lots or air can go into the roll container when the thermal cover is placed over the side-bars. Therefore it is very important that this air is kept to a minimum or an insulated blanket is being placed on top of the goods to protect it from the air above. Also it is important to bring-on the cover in the cold storage room so the air above the goods is the same as the temperature of the goods. Hot air combined with chilled products will have a negative temperature result.

Thermal equilibrium: Always remember that two different temperatures combined in a single thermal packaging system will create a natural thermal equilibrium in which a mutual temperature is created. The final temperature is depending on the thermal energy of each individual product or substance.

Insulation qualities