Multiple use THERMAL COVERS - pallets

- Q-Fold - Thermal cover

- Middle closure - Thermal cover

- IBC container - Thermal cover

- Barrels - Thermal cover

Single use THERMAL COVERS

- Protocol covers

- Protocol covers-DO-U

Single use THERMAL BLANKETS - pallets

- Protocol blankets

- Protocol blankets - SET

- Protocol cross

- Thermal Blankets PMC-ULD

- PMC - ULD insulation system

- BIO Thermal Blankets

Usage of the thermal covers with middle closure for pallets

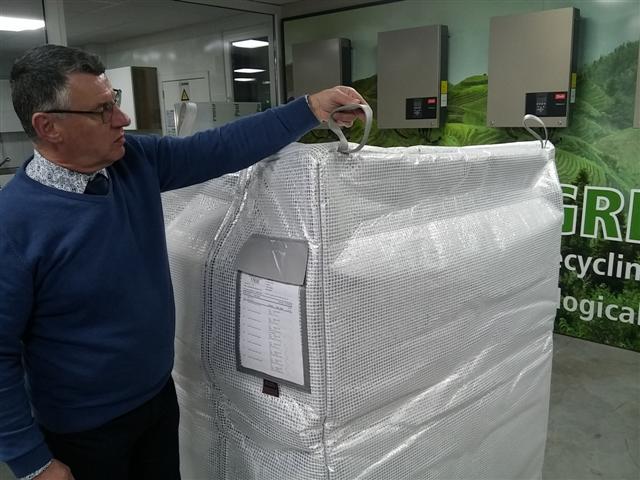

The insulated thermal cover with single middle closure is used as a passive cooling system to maintain and preserve the temperature of temperature controlled (time-temperature sensitive) products such as refrigerated, fresh, chilled or deep frozen food products or pharmaceuticals which are loaded on a pallet. The insulated thermal cover with middle closure is flexible and has only one closure at the front in the middle which makes the cover easy to use and to close. This model is easily pulled over the goods and closed with the velcro closure system. Please notice that this cover needs to be reaching the ground floor to prevent an airflow (open thermal bridge) at the bottom of the goods.

Technical specifications of the thermal cover with middle closure

The thermal cover or insulated cover with middle closure is produced tailor made according to the wishes of the customer. The thermal covers can be produced - manufactured according to required dimensions, colors, models, required insulation quality etc. If you have special requests, just let us know.

MOVIE / Insulated cover for pallets

MOVIE / REMAX thermal cover for insulating pallets

Temperature characteristics

Preservation and stabilization of the product temperature

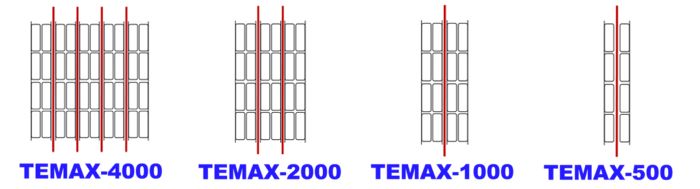

The insulated thermal covers with middle closure are used to preserve or stabilize the temperature of the products, which are protected by the thermal cover, as long as possible. The time that the temperature can be preserved of stabilized, or the speed of temperature increase or decrease, is depending on the insulation quality. Thermal covers or insulated covers with middle closures are manufactured with a certain Temax insulation material which have a certain insulation quality (R-value or U(k)-value). The higher or thicker the insulation quality, the longer the time of temperature preservation or the slower the speed of temperature change of the products inside the thermal cover.

External convection flows due to open thermal bridges – cold bridges

Next to the insulation quality of the thermal cover with middle closure, the stability or deviation speed of the temperature of the product is also depending on the presents of open thermal bridges or open cold bridges on the thermal cover and packaging set-up. Open thermal bridges are locations in the design or set-up of the thermal cover where an external convection flow (air flow) can exist which has a very big impact on the speed of temperature change. It is therefore very important that open thermal bridges are avoided at all times.

Adding extra thermal energy generators - Gel Packs – Dry Ice – PCM’s Phase Change Materials

When conditioned or time-temperature sensitive products are protected from external temperature influences with a passive cooling systems such as thermal covers with middle closure, the goal is to purely use the available thermal energy of the products to maintain and stabilize the temperature of the products as long as possible. As we know, the result of this stabilization is depending on the insulation quality of the thermal cover combined with possible convection flows and the thermal energy of the products combined with the temperature difference (inside-outside). If the temperature cannot be maintained according to the preferred time-frame, the time can be extended by increasing the available thermal energy. This extra energy can be generated by all kind of passive cooling systems such as gel packs – ice packs – dry ice – PCM’s Phase Change Materials.

Insulating the bottom of the pallet

Most pallets have bottoms which are not completely closed so a convection flow (air flow) can appear meaning that the air can flow through these openings. Therefore it is very important to seal or insulate the bottom of the pallet before loading the chilled or frozen products. An insulated bottom will increase the temperature results significant. To insulate the bottom a on-way use insulation or cardboard can be used.

Insulation qualities