You are here: English > Cold Chain > Track & trace

TEMAX Published books

- Cold Chain Implementation Plan

- Advanced Temperature Trailer Mapping

- TRM - Temperature Risk Management

Cold Chain services

- Training and education

- Trailer Mapping

Cold Chain Engineering

- CCRM Cold Chain Temperature risk engineering

- Cold Chain Automation

Material engineering

- Multilayer insulation technique

- Heat transfer engineering

- Insulation configuration blankets

- Building insulation engineering

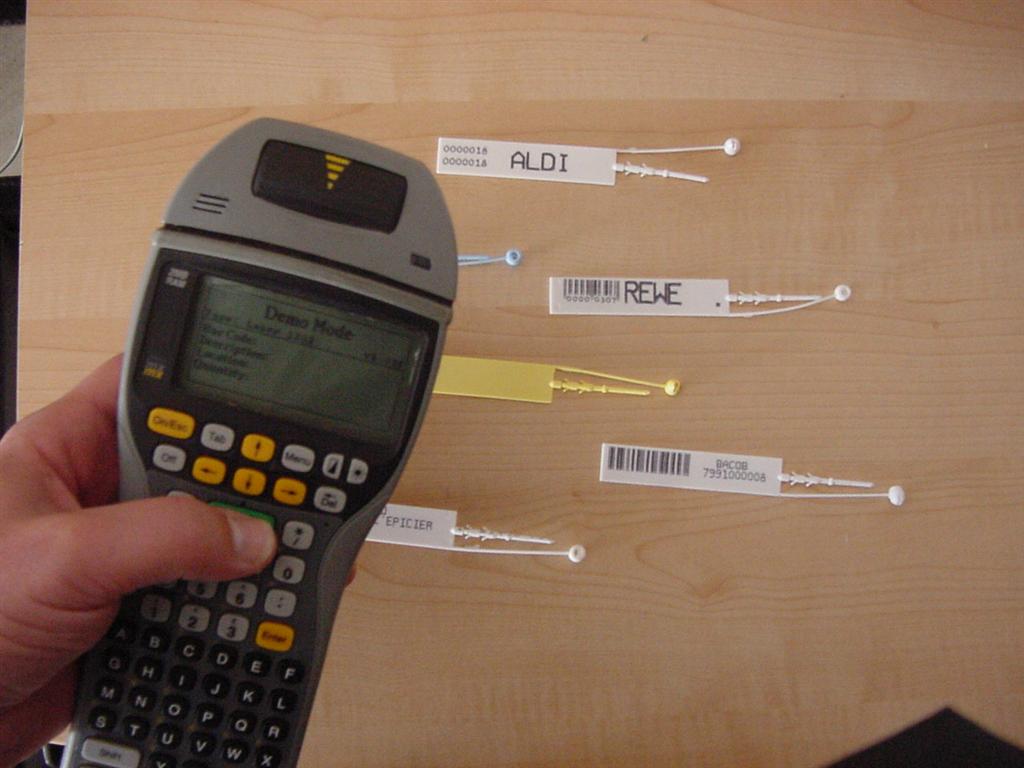

Krautz Temax development and manufacturing of automation Tracking & Tracing systems

Track and trace is a concept from the transport and logistics industry (internal and external) in terms of follow-up and organization. Tracking and tracing means to visualize a time-location or to follow a particular product in the supply chain according to a specific time index. Some companies and organizations have such big structures that it becomes complex to indicate where a product is located in the chain at a certain time. In order to offer a solution to this problem, tracking and tracing systems van be implemented in the supply chain. Its purpose is to create visibility in the product location at a specific time.

Track & Trace of insulated packaging in the cold chain

Tracking and tracing systems are also very important in the design or set-up of a passive cooling system in a cold chain where thermal or insulated packaging systems are used to protect the temperature of time-temperature sensitive products. A track and trace system can be implemented to trace the location and service-status condition of the thermal packaging system at a certain time and the tracking system can be used to create a product quality controlling system of the packed conditioned product. Due to the many advantages of a tracking system on conditioned products in a cold chain, it is even highly advised to implement a good tracking and tracing system on all cold chain set-ups of conditioned products in cold chain logistics

Location-storage + service-status of the thermal packaging through Track & Trace

When track and trace systems are implemented to purely follow or track a thermal packaging device in the supply chain, than the main purpose of the tracking is to determine the storage volumes at a certain location at a certain time and to determine the service-status condition of the thermal packaging device. This way of tracking is therefore mostly used on re-usable thermal packaging systems where the thermal packaging system is transferred often from shipper to destination and vice versa. With this kind of tracking system, the location in the supply chain of a certain thermal packaging device can be visualized combined with the service-status of the thermal packaging device.

Quality controlling - Quality Assurance

A track and trace system can also be implemented on a single use thermal packaging device. When such a single use thermal packaging system is installed with a tracking system, the main purpose will also be to get a visualization of the location of the packaging device in the supply chain or cold chain on a certain time index. Yet an extra advantage can be implemented. When the tracking data is connected to a temperature-read-out data a special quality control management system can be created where T.T.L. data or Time and Temperature and Location become visible. This means that the product quality conditions in the cold chain become clear. In order to be able to create such a quality location tracking management system, a temperature read-out device needs to be connected to the data of the track and trace system. In order to create a closed management system it is also advisable to implement a tracking system that can be used or detected by all actors in the cold chain so each transfer and its time + temperature + location is individually registered.

What do you need to set-up a track and trace system?

To set-up a tracking and tracing system with the goal to follow or track thermal packaging systems in a cold chain or supply chain, three major parts need to implemented; being a tracking product that is being detected, a reading device to read the tracking product and a processing system that can collect and process the data. When all three parts are in place an efficient tracking and tracing management system can be created.

Tracking product

There are different possibilities and applications to create a tracking and tracing system. The most commonly used tracking products are:

- Unique dedicated number per individual thermal packaging device

- Unique dedicated barcode number per individual thermal packaging device

- Unique dedicated RFID tag per individual thermal packaging device

The choice of the ideal tracking product in the specific supply chain is depending on a lot of subjects such as the available technology at each actor in the cold chain or supply chain and the processing of the gathered information data. It is also possible to combine different tracing products in order to create one multiple tracking system. The unique number of a barcode for example can be enlarged and printed under the barcode so the actors in the supply chain can choose to detect and register the unique number or to scan the barcode. Both will generate the same information at the processing unit.

Information collection and processing

Next to a tracking product, the required equipment is required that can read and register the tracking product. When a unique number for example is used as a tracking product, a document can already be sufficient to write down the tracking number. Yet when a barcode or RFID tag is used, more advanced equipment is needed to read-out the tracking product. At last al the collected data needs to be transferred to a processing unit that can process the information.

Statistics and information tables

The main goal of a tracking and tracing system is of course the final information data that is retrieved from the supply chain. Due to the tracking and tracing system it becomes clear where a certain thermal packaging device and its packed product were located on a certain time during the transit in the supply chain. This information offers the great advantage to create a quality controlling management system through the complete supply chain. Greater advantages become even clearer when the retrieved tracking data is connected to temperature-read-out data, creating a full closed and easy to implement quality control management system. Next it is up to the user to publish the processed information and statistics depending on time-frames or even real-time procedures.

TEMAX development and manufacturing of tracking and tracing systems

The company Krautz-Temax has a division that is specialized in the development and manufacturing of tracking and tracing systems for single use or multiple use thermal packaging systems. The main purpose of these tracking and tracing systems is to create a visibility in the location of the thermal packaging systems in the supply chain and to create T.T.L.-data where time and location are connected to a certain location. Krautz Temax develops several tracking products such as unique numbers, barcode numbers and passive RFID tags. All these identification items can be implemented and integrated in the thermal packaging device according to the wishes of the customer.