You are here: English > Cold Chain > Insulation configuration

TEMAX Published books

- Cold Chain Implementation Plan

- Advanced Temperature Trailer Mapping

- TRM - Temperature Risk Management

Cold Chain services

- Training and education

- Trailer Mapping

Cold Chain Engineering

- CCRM Cold Chain Temperature risk engineering

- Cold Chain Automation

Material engineering

- Multilayer insulation technique

- Heat transfer engineering

- Insulation configuration blankets

- Building insulation engineering

Optimal temperature + optimal pay load relation

Thermal blankets and thermal covers function as a passive cooling system and are designed to offer a temperature protection for the transport of time-temperature sensitive goods such as pharmaceuticals and healthcare products (chilled +2°C to +8°C) (ambients +15°C to +25°C), chemicals, food products etc...

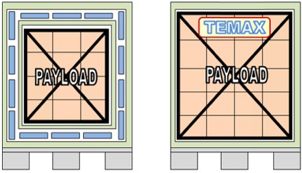

The goal of the usage of thermal blankets or thermal covers is to offer an optimal temperature protection and an ideal pay load relation. This means that the incentive is to use the thermal energy of the shipment to offer the temperature protection. When other passive cooling systems are used such as boxes with gelpacks (see left drawing), it are the gelpacks which create the temperature protection and the thermal energy. Yet these extra gelpacks have a big influence on the payload (extra weight + extra space). This is prevented with the thermal blankets seeing they use the thermal energy of the shipment / goods and are adaptable to the load dimensions of the shipment.

To determine the available thermal energy of the shipment and to determine the needed insulation quality for the temperature protection, the thermal energy flow of the shipment is calculated. This can be done over the total cold chain or for a single temperature excursion.

The ideal insulation configuration for your shipment

When the thermal energy calculations are made, the goal is to determine the ideal insulation quality and the global set-up of the passive cooling system that is required to protect the temperature of the products against the outer or external temperatures. This so HCCP's or "Hazardous Critical Control Points" are avoided where product temperature excursions can appear over or under the product temperature barriers. This calculation will result in a certain insulation configuration or set-up where we also consider the optimal payload situation which is also a major cost factor on cold chain logistics. You will receive a PDF file from us with 10 pages containing the calculated results and the required insulation quality.

Temax YES or NO ? We pre-engineer with thermal energy calculations

The Temax thermal energy calculations are a part of the CCRM "Cold Chain Risk Management" and are used to pre-engineer the temperature flows in a Temax insulated packaging system or passive cooling system. The goal of the thermal energy calculations is to determine the set-up of the Temax thermal packaging system and the required insulation quality to offer an ideal thermal solution. With other words, we make thermal energy calculations especially for your shipment. With this calculation we can determine the most optimal insulation quality and pay load relation in order to offer the ideal temperature protection passive cooling system. All calculations are calibrated to a test qualified or product qualified system. See also page CCRM engineering.

Single temperature excursion or total cold chain calculations

When the thermal calculations are made you can choose between a single temperature excursion calculation or a calculation for the total cold chain as shown below in the red circle. The total cold chain calculation also functions as a C.C.R.M. System "Cold Chain Risk Management" system where the possible HCCP's "Hazardous Critical Control Points" are detected in the cold chain BEFORE the goods are actually transported / shipped which prevents possible product damages due to temperature excursions of the product temperature.