You are here: English > Cold Chain > Multilayer engineering

TEMAX Published books

- Cold Chain Implementation Plan

- Advanced Temperature Trailer Mapping

- TRM - Temperature Risk Management

Cold Chain services

- Training and education

- Trailer Mapping

Cold Chain Engineering

- CCRM Cold Chain Temperature risk engineering

- Cold Chain Automation

Material engineering

- Multilayer insulation technique

- Heat transfer engineering

- Insulation configuration blankets

- Building insulation engineering

What is the meaning of insulation quality at insulation materials - conduction W/m.K

When we take a closer look at insulation materials in general, we can see that actually all sorts of materials have a certain insulation capacity and can offer a certain value of thermal resistance against temperature changes. We can therefore state that all materials, let’s say wood, metals, plastics, but also fluids and air, have the possibility to create a certain thermal resistance or thermal guidance. Due to the molecular construction and set-up of each individual material, each material creates a different thermal resistance and guidance which makes it possible to distinguish good insulating materials and bad insulating materials. How can this be determined? By a specialized test in laboratories where the thermal guidance, also called conductivity, is measured and analyzed. After the test each different material receives a certain conductivity value also called Lambda value which shows the amount of thermal energy that flows through the material in regards to a certain thickness and time. Metal for example has a Lambda value of 76W/m.K where air has a Lambda value of 0,024W/m.K. This means that metal is guiding or conducting more thermal energy than air in the same thickness and time. We can therefore state that air is a better insulating material than metal or we can state; the lower the conductivity or Lambda value, the better the insulation quality and performance in regards to thermal resistance in appearing temperature changes.

What is a multilayer insulation material

When we talk about a multilayer insulation material, we mean that different materials are combined to one single composition to create a new insulation material with a new conductivity or Lambda value and with new thermal resistance and guidance performances. The reason why these multilayer insulation materials are designed can be all kind such as a better thermal performance or a better mechanical quality, such as more flexibility or hardness, that cannot be achieved by each individual material separately. When we look at most combined or multilayer insulation materials we can state that the main purpose of the new composition is to change the insulation performances to create ideal thermal resistance factors for the application in which the new composition is used.

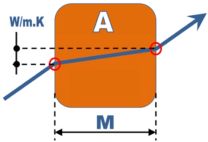

The drawings above show the thermal conductivity (arrow) or the thermal resistance of single layer and multilayer insulation materials. The first drawing on the left shows a single layer insulation material (A) with thickness (M) and a certain thermal conductivity or thermal resistance which is shown by the inclination of the arrow. The steeper the inclination of the arrow, the higher the conductivity or the lower the thermal resistance of the material. When we take a closer look at the first drawing we can also see that the arrow is starting very steep until it reaches the material. The arrow is declining and creating a more horizontal line meaning that the thermal energy or the temperature is experiencing more resistance when it is penetrating the material. At the end of the material we can see that a thermal energy of W/m.K has penetrated through the material. Ones penetrated, the thermal heat is experiencing lesser resistance so the arrow is steeper again.

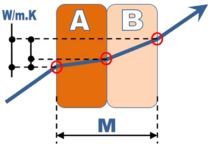

The second drawing shows a multilayer insulation set-up consisting out of two materials (A) and (B) with a combined thickness of again (M). The arrow shows also the thermal conductivity through the materials where the drawing shows that the thermal conductivity of material (B) is bigger (steeper arrow) than material (A). This also means that this combination has a lower thermal resistance than the single layer material meaning that the single layer insulation material is a better insulator than the multilayer composition. The goal of this combination is clearly not to create better insulation performances.

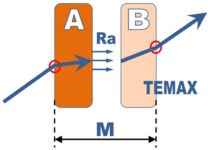

The last drawing on the right shows a special multilayer insulation material where a air-cavity was created between both individual materials (A) and (B). This air-cavity offers the big advantage that the penetrating thermal energy cannot flow directly from (A) to (B) through conduction, but needs to change into radiation (Ra) to reach material (B). This phenomenon creates a big slow-down or delay in the speed of the thermal energy transfer or travel and creates a big increase in the thermal resistance of the total composition being (material A + B + air-cavity). This delay or slow-down of the traveling of thermal energy can even be extra delayed when a passive or active ventilation technique is implemented in the air-cavity.

TEMAX multilayer thermal blanket with closed stationary air and ventilated air-cavities

Temax is a special developed multilayer insulation material or thermal blanket in which several special insulating and thermal resistance techniques are implemented with the goal to create a maximal thermal resistance or insulation quality in regards to a minimal material thickness. The Temax multilayer thermal blanket or foil has been tested by several major pharmaceutical manufacturers for their cold chain logistics and has been nominated and proven to be the best insulation material in its kind.

The T emax insulation material or thermal blankets is a multilayer insulation material that is composed out of special insulation layers and reflection layers. The basic insulation material is built up out of small closed convection cells in which stationary air is generated meaning that a low conductivity (Lambda value) is established that offers great thermal resistance against temperature changes. Within the thermal blankets a number of multiple reflection layers are integrated to offer thermal resistance against heat radiation. The individual reflection capacity of each separate reflection foils is 97% meaning that a low emission factor is created. Due to the high reflection capacity and low emission factor in a multilayer composition built up, the Temax multilayer thermal blanket can offer strong thermal resistance against very high thermal radiation.

emax insulation material or thermal blankets is a multilayer insulation material that is composed out of special insulation layers and reflection layers. The basic insulation material is built up out of small closed convection cells in which stationary air is generated meaning that a low conductivity (Lambda value) is established that offers great thermal resistance against temperature changes. Within the thermal blankets a number of multiple reflection layers are integrated to offer thermal resistance against heat radiation. The individual reflection capacity of each separate reflection foils is 97% meaning that a low emission factor is created. Due to the high reflection capacity and low emission factor in a multilayer composition built up, the Temax multilayer thermal blanket can offer strong thermal resistance against very high thermal radiation.

The drawing on the left shows the Temax-4000 insulation material in which four (4) reflection layers are strategically integrated to offer strong reflection capacities against heavy heat radiation. Within the Temax-4000 material a number of ingenious heat resistance techniques are implemented combined with special passive ventilated air-cavity technologies to generate a flow of heated and cooled air inside the insulation material. This unique technique creates an extra strong thermal resistance against conducting thermal heat through the insulation material.

In short, the Temax insulation material is unique in its kind and can be specified as revolutionary in its category of insulation materials. A number of special insulation techniques and technologies have been implemented into the design to offer a thermal resistance against strong radiation and conduction heat transfer. This also explains why Temax has been nominated to be the best insulator in its kind. Do you have questions in regards of the Temax material, our engineers will be glad to answer your questions.

TEMAX multilayer thermal blanket in cold chain logistics

The Temax multilayer thermal blanket is used in the cold chain logistics (Airfreight – Sea freight – Road freight) to transport time-temperature sensitive products or conditioned products (fresh – frozen – ambient) such as pharmaceuticals or healthcare products, food perishables, chemicals, etc... The Temax multilayer thermal blanket functions as a passive cooling system in which the goal is to protect or preserve the temperature of the product as long as possible during external temperature excursions (hot or cold). The Temax multilayer thermal blankets can be used on rolls, which are cut to size by the user and wrapped according specified protocols and S.O.P’s (Standard Operation Procedures), or they can be tailor made to thermal covers. These tailor made products can be created according to the required dimensions, the required insulation quality, shapes and models, etc… If you have any special requests for multilayer thermal blankets for your cold chain application, please feel free to contact us. Our consultants and engineering will be glad to assist you